Dewatering technology

For thickening and dewatering sewage sludge

During the treatment of wastewater, whether from municipal or industrial wastewater treatment plants, sewage sludge is produced as a residual material with water contents of between 96 % and 99.5 %. This leads to technical problems in all subsequent treatment processes and disposal and increases the structural, mechanical and operational costs. With sewage sludge treatment, there are one or more stages that serve to separate sludge water in order to provide optimized conditions for the subsequent stages. A distinction is made between processes for thickening (up to approx. 15 % DR), dewatering (up to approx. 45 %) and drying (to over 95 % DR).

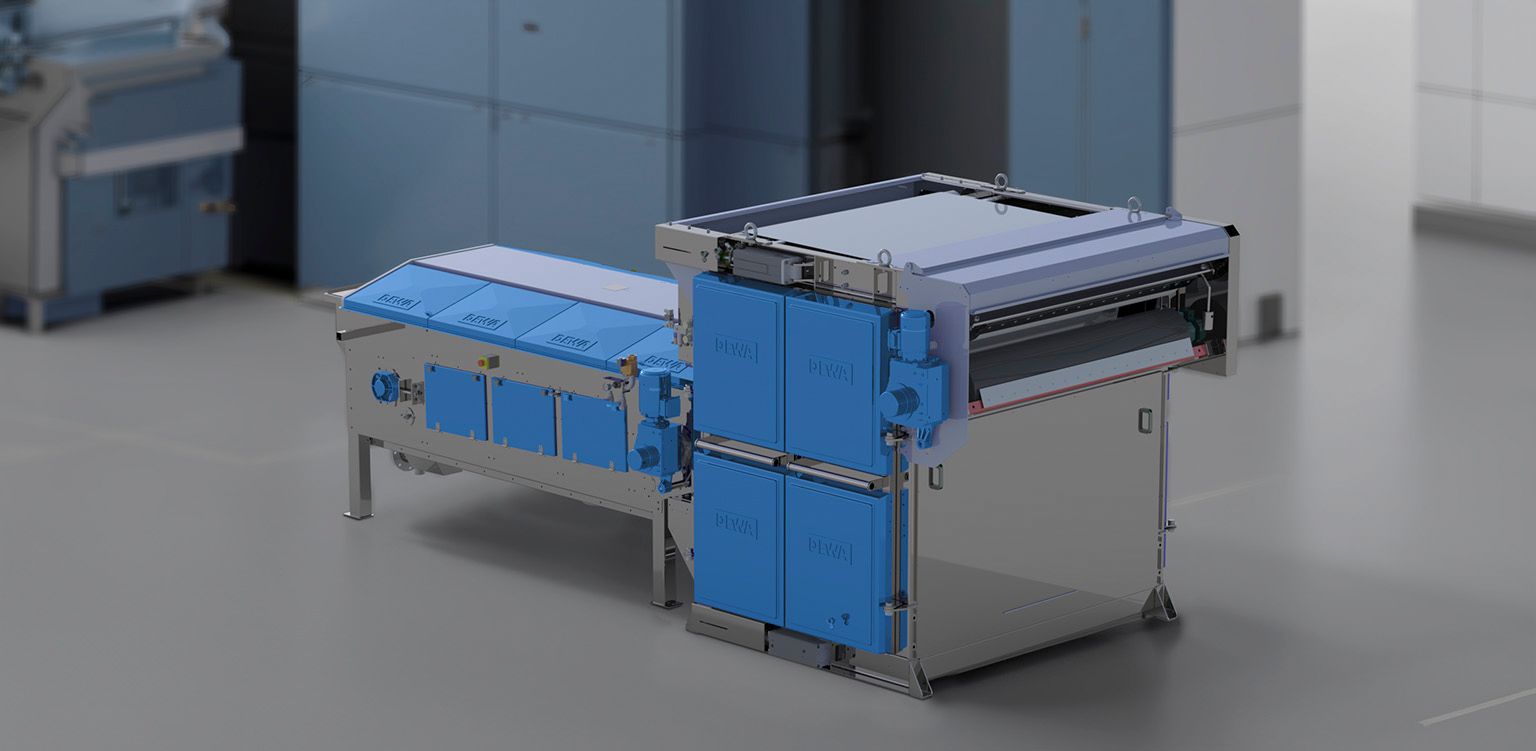

Belt thickeners

DEWA belt thickeners work according to the principle of separating liquid and solids by means of gravity dewatering through a slowly moving filter belt mesh, which significantly increases the dry matter concentration of the sludge fed in. Polymer flocculants are often used to accelerate sludge thickening. These are added to the sewage sludge, for example in an upstream agitator tank, also known as a flocculator, and help to bind finely dispersed particles in the sludge into larger flocs. This makes it easier and quicker to separate the flocs from the liquid.

The closed design of the DEWA belt thickeners enables odors to be contained within the machine and simplifies odor extraction through a ventilation pipe on the top of the cover. The electrical and pneumatic components as well as the bearings are located outside the frame, allowing for easy maintenance and monitoring. High-quality materials and stainless steel components make the belt thickener robust and reliable. Other advantages include reduced energy and polymer consumption with minimal operating and maintenance requirements. The trouble-free operation thus leads to considerable cost savings and reduced workload for the plant management.

Depending on the application and sludge composition, we offer various DEWA belt filter presses for the mechanical dewatering of sewage sludge. The N-PD XL series is a versatile, economical and powerful belt filter press with integrated belt thickener. Thanks to its unbeatable price-performance ratio and low operating costs, it is one of our most popular belt filter presses for municipal and industrial applications. In addition to the N-PD XL series, there are the P-C models for small applications with lower throughputs, the VDP Combo, which is characterized by a large and powerful pressing zone, and the AURA PRESS as a compact solution that fits into containers in all sizes and effectively reduces logistics and transport costs.

All components are made of stainless steel or high-quality plastic that is resistant to most corrosive media. This, combined with the easy accessibility and serviceability of key parts, guarantees reliable operation and a very long service life that lasts for decades. The machines are characterized by high efficiency, compact design and low energy consumption and maintenance requirements. Water-saving operation through the use of filtrate for belt cleaning is a matter of course. On request, we can also supply optional accessories for sludge conditioning such as flocculators and polymer preparation stations as well as screw conveyors and control units.