Scrapers

For removal of bottom and floating sludge in sedimentation tanks

Scrapers are mechanical devices for clearing settled sludge or floating sludge in a sedimentation tank. Our scrapers can be found in all types of sedimentation tanks, both in municipal and industrial wastewater treatment plants and in waterworks. The basin geometry can be rectangular or round.

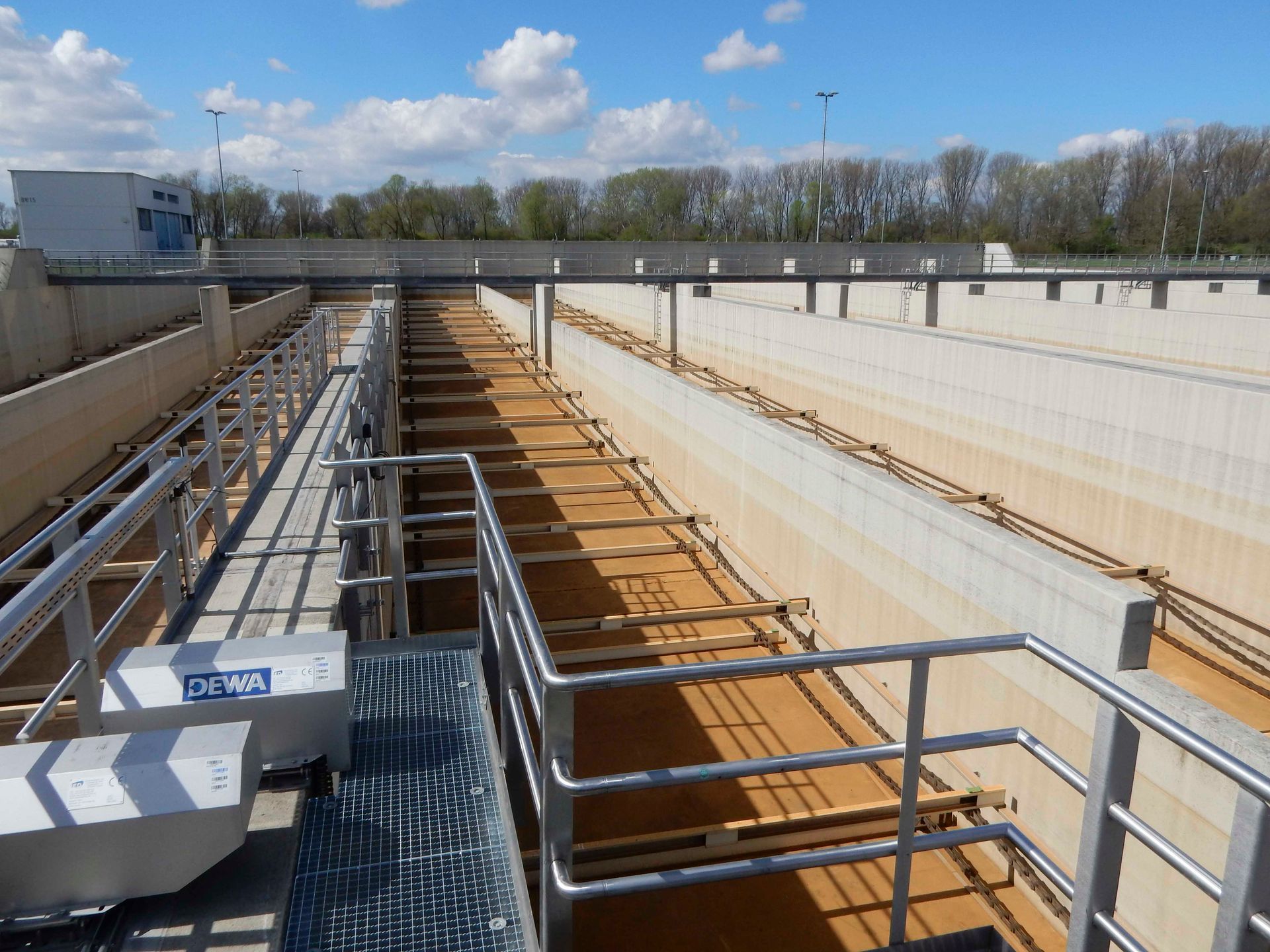

Plastic chain scraper

Our DEWA® plastic chain scraper is ideal for the continuous removal of bottom and floating sludge in rectangular sedimentation tanks. It is most frequently used as a bottom and floating sludge scraper in primary and secondary clarifiers in municipal sewage treatment plants. However, it can also be used in grit and grease traps, in flotation tanks or in waterworks under lamella separators as a pure bottom or floating sludge scraper in a 2- or 3-shaft design.

Special versions in ATEX for API tanks in the petrochemical industry, in duplex steel for seawater applications or for the removal of trace substances in PAC (Powdered activated carbon) sedimentation tanks are also possible.

The advantages of the DEWA® plastic chain scraper lie in the system design and the choice of materials for the individual components. Load-bearing parts such as shafts and rails are made of stainless steel, while moving parts are made of lightweight plastics or GRP. This results in high stability, extreme durability, very low wear and enormous savings in maintenance and energy costs.

Nature's Symphony

Longitudinal scraper bridges can also be used to clear bottom and floating sludge in rectangular tanks. In primary clarifiers they are usually used as scraper blades, in secondary clarifiers often also as suction scrapers and in grit and grease traps as well.

The scraper blades ensure that all the bottom sludge in the tank is transported into the sludge hoppers and the floating sludge into the designated floating sludge channels. This is referred to as a discontinuous clearing process, as the scraper only clears in one direction (outward or return journey).

The other option for continuous sludge removal is suction scrapers. Depending on customer requirements, the sludge is pumped or conveyed through evacuated siphon pipes into a collecting channel.

The longitudinal scrapers can be designed as rail-free, with rubber-tyred drive and guide wheels or as positively driven scraper bridges with rails and toothed rack.

Travelling Bridge Scraper

Rotating Bridge Scraper

Circular scrapers are used in circular sedimentation tanks with horizontal flow. They are mainly used in primary and secondary clarification in both municipal and industrial wastewater treatment plants.

We differentiate between rotating bridge scrapers and fixed bridge scraper also known as centrally driven scrapers or Thickeners. Rotating bridge scrapers are mounted centrally on the central column “Königsstuhl” (slewing ring) and driven externally via a chassis. Depending on the basin diameter and sludge volume, full bridge types (two-armed) or semi bridge types (single-armed) are used. The circular scrapers can be designed as shield or suction scrapers for bottom sludge removal. The floating sludge can be removed in different ways, for example by means of a skimmer blade and lateral scum collection box, via one or more rotating scum chutes, by a paddle mechanism or by means of a screw conveyor. Our round scraper bridges are driven by polyurethane-coated heavy-duty wheels or alternatively by rubber wheels. Special designs with numerous options and accessories are available on request.

Fixed bridge scrapers also known as centrally driven scrapers or Thickeners, are often used in covered or underground circular tanks at municipal and industrial wastewater treatment plants. They are used for sludge removal or as a Thickener with picket fence for sludge thickening.

A vertical shaft is driven by a drive motor with a centrally arranged ball bearing slewing ring, to which either two or four scraper arms with louver-shaped scraper blades, with or without picket fence, are flange-mounted and braced. The construction is supported by a concrete or steel bridge. Due to the slow rotation of the shaft, the scraper blades push the bottom sludge to the central sludge hopper, from where the sludge is removed. The bars of the picket fence draw channels into the sludge zone through which the trapped water can rise and the sludge is thickened.

Additional accessories such as inlet cylinders, floating sludge clearing device and turbid water discharge with baffle and weir can be supplied on request.